To troubleshoot cold ferment versus room temp issues, first guarantee your environment stays stable because fluctuations can stall fermentation. For cold ferments, extend the time or slightly warm the environment if activity slows. At room temperature, check nutrient levels and verify equipment calibration. Use sensory cues like bubbling or pH changes to guide adjustments, and consider moving to a more consistent zone if problems persist. Keep troubleshooting tips handy to master your fermentation process.

Key Takeaways

- Maintain stable temperatures using data loggers and alarms to prevent fluctuations that stall fermentation.

- Adjust fermentation zones based on activity signs—move to warmer or cooler environments as needed.

- Regularly calibrate thermometers and equipment for accurate temperature control.

- Use gentle agitation or nutrient supplementation to restart sluggish fermentation in cold or room temps.

- Monitor sensory cues like bubbling, pH, and aroma to determine optimal timing and environment adjustments.

Differences in Temperature Control and Their Effects on Fermentation

Temperature control plays a crucial role in fermentation, as even small changes can profoundly impact the process. Maintaining temperature stability is essential because fluctuations can disrupt fermentation kinetics, slowing down or halting activity altogether. When you keep the environment consistently cool, you slow fermentation, which often results in cleaner flavors and better control over byproducts. Conversely, higher temperatures accelerate fermentation kinetics, speeding up the process but increasing the risk of off-flavors or undesirable compounds. Precise temperature control helps you predict and manage fermentation behavior, ensuring consistent results. Whether opting for cold ferment or room temperature, understanding how temperature influences fermentation allows you to troubleshoot and optimize your process for the desired outcome. Glycolic acid is an example of a skincare ingredient that benefits from stable conditions to maintain its efficacy during application and storage.

Common Troubleshooting Challenges at Room Temperature and How to Solve Them

When fermenting at room temperature, you might encounter issues like inconsistent activity, off-flavors, or stalled fermentation, which can be frustrating to troubleshoot. One common challenge is uneven yeast activity, often caused by uneven nutrient availability. If yeast isn’t getting enough nutrients, fermentation slows or stops altogether. To fix this, ensure your wort or mash has sufficient nutrients and consider adding yeast nutrients if needed. Temperature fluctuations can also impair yeast performance, so keep your fermenter in a stable environment. Additionally, watch for contamination, which can produce off-flavors and hinder yeast health. Regularly monitor your fermentation process, and if activity stalls, gently agitate or swirl the fermenter to redistribute nutrients and yeast cells. Proper nutrient management and consistent temperature are key to maintaining healthy yeast activity. Being aware of the specific types of dog breeds involved can help you better understand and manage the characteristics of your fermentation environment.

Troubleshooting Cold Fermentation: Addressing Common Issues

Cold fermentation presents unique challenges that differ from room temperature issues, requiring different troubleshooting approaches. If your yeast activity seems sluggish, verify the fermentation environment isn’t too cold, which can slow down yeast metabolism. Avoid excessive oxygen exposure, as it can cause off-flavors or spoilage. Proper sealing helps maintain oxygen levels and prevents contamination. Use the table below to quickly identify common cold fermentation issues and solutions:

| Issue | Solution |

|---|---|

| Yeast not activating | Warm slightly or increase fermentation temp |

| Off-flavors or spoilage | Minimize oxygen exposure and maintain hygiene |

| Slowed fermentation | Ensure yeast viability and proper temperature |

| Mold or surface growth | Improve sealing and reduce oxygen contact |

A well-maintained environment is essential for successful cold fermentation and avoiding common pitfalls.

Managing Off-Flavors in Room Temperature Ferments

Managing off-flavors in room temperature ferments requires attentive control over your process, as subtle changes can substantially impact flavor development and aroma preservation. To prevent undesirable tastes, monitor your fermentation closely, ensuring temperature stays consistent and avoid sudden fluctuations. Proper sanitation reduces contamination risks that cause off-flavors. Regularly taste and smell your ferment to catch early signs of off-notes, adjusting if necessary. Using clean equipment and maintaining optimal pH levels also helps preserve aroma and prevent sour or off-putting flavors. Keep your environment well-ventilated to avoid mold or bacterial growth that can compromise flavor quality. Additionally, understanding how color accuracy in your environment can influence your perception of aroma and taste helps in maintaining overall flavor integrity. By staying vigilant and making small adjustments, you can effectively manage off-flavors, ensuring your room temperature ferment develops desirable flavors while maintaining aroma integrity.

Adjusting Fermentation Times for Optimal Results in Both Methods

Fine-tuning fermentation times can substantially influence the final flavor and aroma of your produce, whether you’re using cold ferment or room temperature methods. To do this effectively, you need accurate temperature calibration of your environment and equipment. Slight variations in temperature can affect fermentation timing, so monitor your setup closely. Adjust the duration based on sensory cues—taste, smell, and appearance—rather than fixed timelines. For cold ferment, extend the fermentation period if the temperature dips lower than ideal, slowing down the process. Conversely, in room temperature methods, shorten the time if fermentation accelerates too quickly. Consistent temperature calibration ensures your timing remains predictable, helping you achieve *best* results without over- or under-fermenting. Remember, precise timing is key to flavor development. Additionally, understanding the impact of temperature on fermentation can help you troubleshoot more effectively and tailor your process for optimal outcomes.

Monitoring and Correcting Ph Levels During Fermentation

Monitoring and correcting pH levels during fermentation is essential to guarantee your product develops the desired flavor and safety. Regular pH balancing helps you maintain ideal acidity control, preventing undesirable bacterial growth and off-flavors. Use a reliable pH meter to check levels frequently, especially during the early stages. If the pH drifts too low or high, adjust accordingly—adding acid or alkaline substances as needed. Cold fermentations tend to stabilize pH more gradually, so monitoring becomes even more critical to avoid imbalances. Consistent pH management ensures your fermentation stays on track, producing a well-rounded, safe product. Keep a log of pH readings to observe trends and make precise corrections, ensuring your fermentation process remains controlled and predictable.

Dealing With Unexpected Stalls or Slow Fermentation

When your fermentation stalls or slows unexpectedly, it’s vital to identify what might be causing the issue. Common triggers include temperature fluctuations, under- or overfeeding, or contamination. Understanding these factors helps you apply effective troubleshooting strategies to get your fermentation back on track. Additionally, maintaining a consistent temperature, such as proper fermentation temperatures, can significantly influence fermentation progress.

Identifying Fermentation Stall Triggers

Unexpected stalls or slow fermentation can be frustrating, but identifying the underlying triggers is crucial to getting things back on track. First, check your starter culture—if it’s weak or past its prime, fermentation will slow or stall entirely. Freshness matters; old or improperly stored ingredients may lack the active microbes needed for a healthy ferment. Temperature plays a role too: too cold can hinder yeast activity, while too warm might cause undesirable bacteria growth. Also, ensure your environment isn’t contaminated—unwanted microbes can interfere with fermentation. Pay attention to smell, appearance, and bubbling activity; these clues help pinpoint the trigger. By systematically evaluating your starter culture, ingredient freshness, and environment, you’ll better understand what’s causing the stall and how to fix it. Monitoring environmental conditions is essential because temperature fluctuations can significantly impact fermentation progress.

Effective Troubleshooting Strategies

Facing a fermentation stall can be frustrating, but having a clear plan to troubleshoot helps you get back on track quickly. First, check yeast activity—look for signs like bubbles or a sour smell. If activity is low, consider gently warming the dough or adjusting temperature to encourage fermentation. Review your fermentation timeline; sometimes, slow progress simply means patience is needed. If your dough remains sluggish, try gently kneading to redistribute yeast or adding a small amount of fresh yeast if appropriate. Keep a detailed record of your process to identify patterns or triggers for stalls. Remember, yeast activity varies with temperature and ingredients, so adapting your approach based on these factors is key to maintaining steady fermentation. Additionally, understanding automation in business can help you optimize your process and reduce manual troubleshooting, ensuring more consistent results. Proper troubleshooting guarantees a more predictable and successful baking experience.

Tips for Maintaining Consistent Temperatures in Both Environments

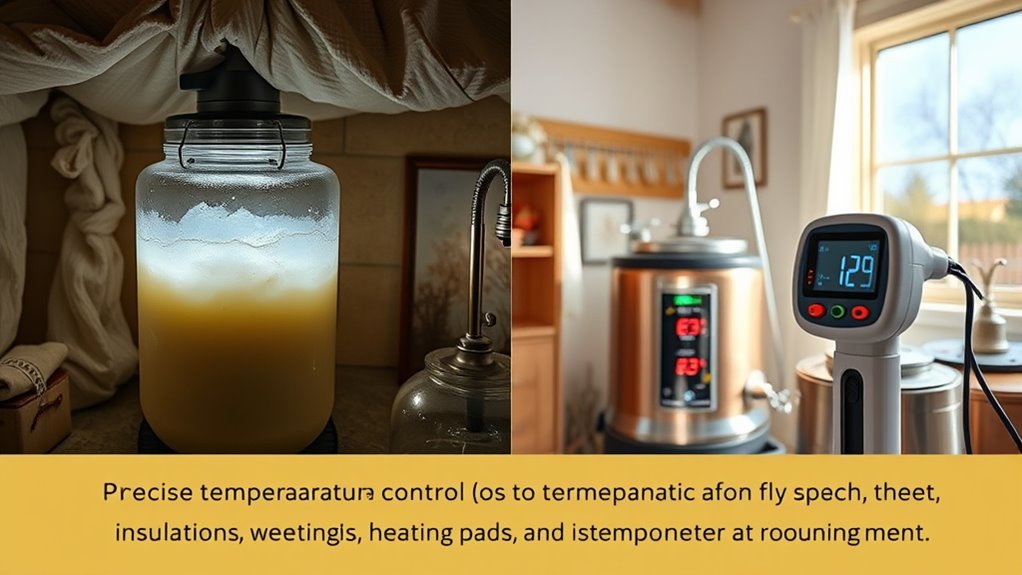

Maintaining consistent temperatures in both cold ferment and room temperature environments requires careful monitoring and proactive adjustments. To guarantee temperature stability, regularly check your equipment calibration; inaccurate thermometers can lead to fluctuations. Use a reliable thermometer and calibrate it frequently to keep readings accurate. Keep your environment consistent by controlling airflow, avoiding drafts, and maintaining stable humidity levels. For cold fermentation, use insulated containers or barriers to prevent temperature drops; for room temp, position your fermenting vessel away from heat sources. Track temperatures with a digital data logger or thermometer, and set alarms for deviations. These steps help you maintain a steady environment, reducing the risk of inconsistent fermentation and ensuring your results remain predictable.

When to Consider Moving Your Ferment to a Different Temperature Zone

If your fermentation is moving too slowly or shows signs of inconsistency, it might be time to change temperature zones. Temperature fluctuations can hinder the process or cause unwanted variations, so finding the optimal zone is essential. Consider adjusting your ferment to a different area when these signs appear to keep things on track.

Signs of Slow Fermentation

Slow fermentation often signals that your current temperature isn’t ideal for the process. When this happens, watch for these signs:

- Poor rising activity – your dough or brew shows minimal bubbles or expansion, indicating low yeast vitality.

- Unusual pH levels – if the pH balance remains stagnant or doesn’t shift as expected, fermentation is lagging.

- Extended fermentation time – if the process takes considerably longer than typical, it’s a sign the temperature isn’t supporting best yeast activity.

These signs suggest that your yeast isn’t performing efficiently due to subpar temperatures, affecting yeast vitality and pH balance. Moving to a different temperature zone can help jumpstart fermentation and ensure a healthier, more active process.

Temperature Fluctuation Effects

When fermentation signs indicate sluggish activity, fluctuations in temperature might be be the culprit. Temperature stability is essential for consistent fermentation, as even minor fluctuation impacts can slow down or stall the process. If your environment experiences frequent temperature swings, it’s time to consider moving your ferment to a different zone. Sudden changes can disrupt yeast activity and lead to uneven results. Maintaining a steady temperature allows the yeast to work efficiently, ensuring proper flavor development and consistent fermentation times. If your current spot experiences temperature fluctuations, it’s a clear sign you should find a more stable environment. Keeping your ferment in a consistent temperature zone minimizes fluctuation impact, helping your brew reach its ideal potential without unnecessary delays. Additionally, understanding temperature regulation methods can help you create a more controlled fermentation environment.

Optimal Zone Identification

Identifying the ideal temperature zone for fermentation is essential to guarantee consistent and healthy yeast activity. When your fermentation stalls or produces off-flavors, it’s time to evaluate if your current zone maintains temperature stability. Consider moving your ferment if:

- The temperature consistently drifts outside the optimal fermentation zones for your yeast strain.

- You notice irregular bubbling or slow activity, indicating the zone isn’t stable enough.

- External factors cause frequent fluctuations, disrupting yeast performance.

Switching to a more suitable zone can improve yeast health and product quality. Recognizing when to adjust your fermentation environment ensures you maintain consistent results and avoid setbacks caused by unsuitable temperature stability. Proper zone identification is key to successful fermentation.

Frequently Asked Questions

How Do I Know When My Fermentation Is Complete?

You’ll know your fermentation is complete when it has reached the expected duration for your recipe, usually 24-72 hours, depending on temperature effects. Check for a consistent, slightly bubbly surface and a tangy aroma. If it passes the taste test and the bubbles slow down, it’s ready. Keep in mind, colder temperatures slow fermentation, so adjust your timing accordingly, and trust your senses to determine when it’s perfect.

Can I Switch Between Cold and Room Temperature Mid-Process?

Yes, you can switch between cold and room temperature during fermentation, but beware—temperature fluctuations can turn your process into a wild rollercoaster. Sudden changes may disrupt fermentation consistency, causing unpredictable results. To keep things smooth, try to minimize temperature shifts or make small adjustments gradually. This way, you maintain better control and ensure your dough develops evenly, avoiding surprises that could ruin your baking masterpiece.

What Signs Indicate My Ferment Has Gone Bad?

If your fermentation has gone bad, look for signs like abnormal fermentation speed—either too slow or too fast—and mold growth on the surface. You might also notice an off smell or strange discoloration. These indicators suggest contamination or spoilage. Trust your senses: if it smells sour or funky beyond normal fermentation, and you see mold, it’s best to discard it to stay safe.

How Do I Adjust Recipes for Different Temperature Settings?

Adjusting recipes for different temperatures is like tuning a guitar string—small changes make a big difference. For temperature adaptation, reduce fermentation time if it’s warmer, since yeast activates faster, and extend it if it’s cooler. When making recipe modifications, keep an eye on dough development and proofing times, and be ready to tweak hydration or fermentation durations accordingly. This way, your bread turns out perfect regardless of your kitchen’s climate.

Is There a Risk of Contamination When Changing Temperatures?

Changing temperatures can increase the risk of contamination because microbial growth varies with temperature fluctuations. When you alter your fermentation environment, you might accidentally introduce bacteria or mold if surfaces or ingredients aren’t properly sanitized. To minimize this risk, keep consistent temperatures, maintain cleanliness, and monitor your setup regularly. This way, you prevent unwanted microbial growth and make certain your fermentation stays safe and successful.

Conclusion

When troubleshooting fermentation issues, remember that temperature plays a vital role. For example, imagine you’re fermenting a sourdough and notice it stalls at room temperature—by shifting it to a slightly warmer spot, you can revive it. Staying attentive and adjusting your environment guarantees consistent, flavorful results. Don’t be discouraged—each challenge is a chance to learn. With patience and careful monitoring, you’ll master both cold and room temperature ferments.